In the modern landscape of packaging solutions, tinplate packaging has become a leading selection for food, specifically in the world of metal food packaging. The versatility, resilience, and recyclability of tinplate make it an optimal material not only for canisters yet additionally for different lid and packaging designs customized to satisfy specific market demands. Allow's explore the diverse world of food can lids packaging, consisting of the manufacturing processes and innovations that satisfy an ever-evolving consumer base. Can lid manufacturing requires accuracy and precise focus to high quality, especially taking into consideration the varied features that these lids serve. They have to make sure the honesty of the product, supply a hermetic seal to preserve quality, and endure the roughness of transport and storage space. Notably, the can lid packaging solutions have to also straighten with global food safety and security standards, which better elevates the relevance of using top notch tinplate materials.

As the popularity of canned foods proceeds to increase, driven by their convenience and long shelf life, the demand for trusted food can lids packaging has actually considerably increased. The appearances of can lid packaging must not be neglected, as vibrant shades and engaging layouts can catch a consumer's interest on the shelf, making the item stand out in a congested marketplace.

Their know-how in can lid packaging solutions, specifically within the metal food packaging domain, enables them to help businesses in choosing the appropriate packaging that aligns with product demands while additionally pleasing regulatory guidelines. The process of choosing food can lids packaging goes beyond simply picking a lid; it entails considering elements such as compatibility with existing can styles, the nature of the product being secured, and the preferred rack life.

Custom lids can be created in various sizes, shapes, and arrangements, depending on the type of food product and the market segment it aims to serve. The developments in innovation have made it possible for producers to create specialized lids that feature functionalities such as tamper-evident designs or easy-pour spouts, enhancing usability and safety for end-users. In today's fast-paced world, consumers are increasingly deciding for convenience, and packaging solutions that accommodate such needs are crucial. The manufacturing process for can lids usually entails detailed actions that need high get more info precision machinery to make certain the appropriate fit and mechanical properties necessary for reliable securing. The automated processes adopted by suppliers have actually substantially boosted efficiency, permitting the automation of lids that do not compromise on top quality.

Metal packaging is commonly pertained to as one of the most lasting packaging forms due to its recyclability and the decreased carbon impact linked with its production and recycling compared to plastics. The food can lids packaging market not just advantages from this sustainable angle but also plays a vital duty in advertising environmentally pleasant techniques throughout the more comprehensive food packaging sector.

Collaborating with professionals such as Uniteam Sourcing can provide makers with valuable understandings read more into the most current trends in can lid packaging solutions. Maintaining abreast of developments in materials scientific research can lead to considerable innovations in the performances of food can lids.

Unique and captivating graphics can be printed directly onto the lids, turning them into a sensory experience that not only secures the food yet additionally tells a tale regarding the item within. Creative labeling on can lid packaging can connect users to the product, share its origins, or offer complementary serving tips, hence boosting the total customer experience.

To underpin effective can lid manufacturing, it's crucial that organizations team up closely with their supplier companions, like Uniteam Sourcing, to make certain that the products made use of fulfill not just useful but additionally visual objectives. By keeping open networks for interaction and comments, providers can better develop solutions that adapt quickly to changing customer demands and choices. The agility of the production process is essential in aiding companions change quickly to brand-new market fads or regulative requirements in food packaging.

As we dig much deeper into the future of tinplate packaging solutions, one point is certain: the value of food can lids packaging will proceed to rise. As ecological understanding expands, the demand for recyclable products, such as metal lids, will certainly even more strengthen the metal packaging market.

In final thought, tinplate packaging solutions offer a durable and flexible system for food can lids packaging, shaped by both performance and design. As we look onward, the harmony in between technology, design, and responsible resource management will define the future of food can lids packaging, reinforcing the essential role that custom lids play in the lifecycle more info of metal food packaging systems.

Jaleel White Then & Now!

Jaleel White Then & Now! Alexa Vega Then & Now!

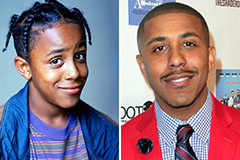

Alexa Vega Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Shane West Then & Now!

Shane West Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now!